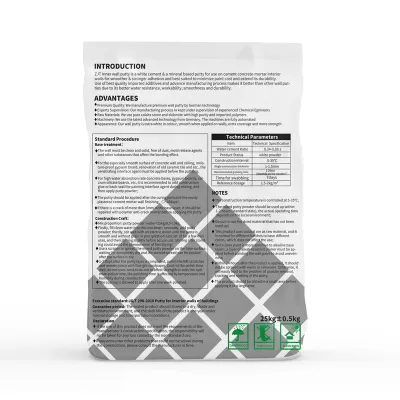

INTRODUCTION

ZJT nner wall putty is a white cement & a mineral based putty for use on cement concrete-mortar interiorwalls for smoother & stronger adhesion and best suited to minimize paint cost and extend its durability.Use of best quality imported additives and advance manufacturing process makes it better than other wall putties due to its better water resistance, workability, smoothness and durability.

ADVANTAGESP

remium Ouality: We manufacture premium wall putty by German technologyExperts Supervision: Our manufacturing process in kept under supervision of experienced Chemical EgnineersRaw Materials: We use pure calcite stone and dolomite with high purity and imported polymersMachinery: We use the latest advanced technology from Germany. The machines are fully aotomatedAppearance: Our wall putty is extra white in colour, smooth when applied on walls, extra coverage and more strength

Standard Procedure

Base treatment:

The wall must be clean and solid, free of dust, mold release agentsand other substances that affect the bonding effect.

For the especially smooth surface of concrete wall and ceiling, mois-ture-proof gypsum board, renovation of old ceramic tile and etc., thepenetrating interface agent must be applied before the puttying.

For high water absorption rate concrete bases, gypsum boards, cal-cium silicate boards, etc, it is recommended to add constructionglue or back-seal the painting interface agent during mixing, andthen apply putty powder;

The putty should be applied after the curing period of the newlyplastered cement mortar wall finishing.(>14days)lf there is a crack of more than 3mm in the base layer, it should berepaired with polymer anti-crack mortar before applying the putty.

Construction Craft:

Mix proportion:putty powder: water=25kg/9.5-10kgFirstly, fill clean water into the container; secondly, add puttypowder; thirdly, stir well with an electric mixer until the paste issmooth and without grain or precipitation; last, let sit for a few min-utes, and then stirring slightly before actual use. (stirring after standing could avoid the phenomenon of fast drying)Use a scraper to spread the mixed putty powder on the base surface.waiting for completely dry and the second spread can be appliedafter the surface is dry.

1-2 days after the putty layer is completed, polish the left scratchesand uneven place with fine grit sandpaper, Controlthe polish timewell, do not over-sand so as not to affect strength or miss the opti-mum polish time, the polishing time is affected by temperature andhumidity during construction.

The coating is allowed to apply after one week polished.

NOTES

The construction temperature is controlled at 5-35°C;The mixed putty powder should be used up within1-2 hours (standard state), the actual operating timedepends on the localenvironment;Do not re-use the dried material that has not beenused up;

This product uses natural ore as raw material, and itis normal for different batches to have differentcolors, which does not affect the use;Since latex paint is more sensitive to alkaline baselayers, a layer ofalkali-resistant primer must be ap-plied before painting the wall paint to avoid uneven-ness;Within 24 hours after the product is applied, it shouldnot be sprayed with water or rainwater. Otherwise. itwill easily lead to the problem of powder removal,cracking and shelling of the putty;This product should be tested in a small area beforeapplying it in a large area.