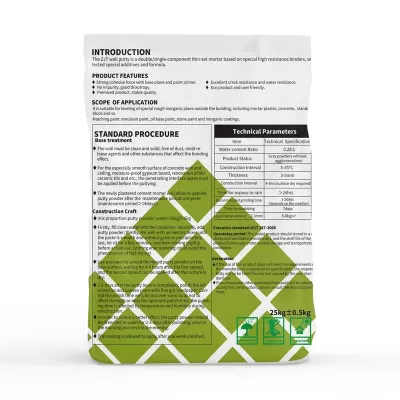

INTRODUCTION

The ZJT wall putty is a double/single-component thin-set mortar based on special high resistance binders, selected special additives and formula.

PRODUCT FEATURES

Strong cohesive force with base plane and paint primer.

No impurity, g otropy.

Premixed product,stable quality.

Excellent crack resistance and water resistance.

Eco product and user friendly.

SCOPE OFAPPLICATION

it is suitable for leveling of special rough inorganic plane outside the building, including mortar plaster, concrete, standardblock and soMatching paint: emulsion paint, oil base paint, stone paint and inorganic coatings.

STANDARD PROCEDURE

Base treatment

The wall must be clean and solid, free of dust, mold re-lease agents and other substances that affect the bondingeffect.

For the especially smooth surface of concrete wall andceiling, moisture-proof gypsum board, renovation of oldceramic tile and etc., the penetrating interface agent mustbe applied before the puttying.The newly plastered cement mortar wall allow to appliedputty powder after the maintenance period complete(maintenance period>14days)

Construction Craft

mix proportion:putty powder/ water=20kg/5-6kgFirstly, fill clean water into the container; secondly, addputty powder; thirdly, stir well with an electric mixer untilthe paste is smooth and without grain or precipitation;last, let sit for a few minutes, and then stirring slightlybefore actual use. (stirring after standing could avoid thephenomenon of fast drying)

Use a scraper to spread the mixed putty powder on thebase surface, waiting for 4-6 hours after the first spreadand the second spread can be applied after the surface isdry.

1-2 days after the putty layer is completed, polish the leftscratches and uneven place with fine grit sandpaper. Con.trol the polish time well, do not over-sand so as not toaffect strength or miss the optimum polish time, the polishing time is affected by temperature and humidity duringconstruction. In order to obtain a better effect, the putty powder shouldbe drenched in water for 2-3 days after polishing, once inthe morning and once in the evening.The coating is allowed to apply after one week polished.